Computational fluid dynamics

Our CFD development activities represent a significant collective effort, with one of the largest groups of research and development in the world. Our expertise spans a wide range of techniques, from industrial finite volume method to smoothed particle hydrodynamics, lattice Boltzmann method, and novel approaches for high order numerics. We actively develop and champion a range of open-source software.

-

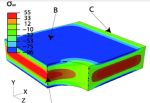

Industrial finite volume

Manchester has delivered a long list of developments in CFD over the past 4 decades, with significant focus on codes employing the finite volume method. Many of which have found their way into widely used computational engineering software; both commercial and opensource. The breadth of our work has enabled cross-fertilisation of ideas across sectors, and we have gained a world-wide reputation in this activity.

-

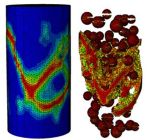

Smoothed particle hydrodynamics

Smoothed particle hydrodynamics (SPH) is a mesh-free method for simulating free-surface and multiphase flows. Manchester's SPH group excel have made a host of innovations that extend and improve the predictive accuracy and range of application of this approach, with a particular focus on coastal engineering and natural hazards.

-

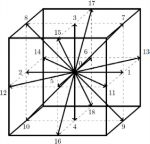

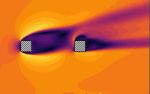

Lattice Boltzmann methods

Lattice Boltzmann methods (LBM) simulate fluid dynamics using particle distribution functions, which excel for complex geometries and multiphysics flows. At the University of Manchester, research in LBM has advanced predictive accuracy of turbulent flows, fluid structure interaction, and flows with complex multiphysics, including plasmas and multicomponent flows.

-

High order methods

We are developing high-order meshless methods for direct numerical simulations (DNS) in complex geometries. These methods offer accuracy comparable to high-order finite differences, support arbitrary geometries, achieve up to 10th-order convergence, and provide variable resolution and dynamic adaptivity. Scalable to thousands of cores, they enable efficient, high-fidelity simulations for applications like turbulence and visco-elastic flows.

Computational solid mechanics

Our computational solid mechanics activities represent one of the most comprehensive research efforts globally. Our expertise ranges from traditional finite element methods to novel discrete approaches, applyied to challenges in nuclear, aerospace, and civil engineering sectors. The diversity of our approaches enables cross-fertilisation of ideas and methods across different material systems and application domains.

-

Finite element method

We enhance finite element methods (FEM) for complex material behaviour, covering multi-phase modelling, crystal plasticity, cohesive zones, and damage mechanics. Our work includes developing new element formulations and applying FEM to tough issues like quasi-brittle fracture, weld stress prediction, and composite failure. We emphasise parallel computing via ParaFEM, enabling large-scale simulations on high-performance systems.

-

Discrete Physical Mathematics

We have pioneered Discrete Physical Mathematics (DPM) to model materials and processes directly on their topological architecture. At its core is Combinatorial Mesh Calculus (CMC), developed by our group, which formulates transport and mechanical phenomena as cell interactions in a complex, enabling rigorous variational descriptions of diffusion, deformation, fracture without reference to a background continuum. Bridging particle-based and continuum approaches, DPM captures evolving microstructures and topological transitions like void formation and crack propagation. Already applied to mass transport, heat conduction, fluid flow in porous media and charge migration, it now underpins our initiative extending discrete topological modelling to engineering and materials design applications.

-

Particle methods

We develop peridynamic formulations for modelling discontinuous phenomena such as fracture, erosion, and multi-phase flow in porous media. Our work includes both theoretical advances in bond-based and state-based peridynamics, as well as practical implementations for problems involving phase transitions, heat transfer with solidification/melting, and coupled thermo-hydro-mechanical processes in geomaterials.

-

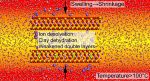

Ab initio methods

We employ quantum-mechanical and atomistic simulations to reveal fundamental material behaviour and to model coupled thermo-chemo-mechanical processes from first principles. Our work focuses on nano-porous materials, where thermal osmosis and thermal diffusion govern transport and energy conversion, and on chemical reactions in early-stage cement systems containing reinforcing nanoparticles. We develop multi-scale approaches that bridge density functional theory, molecular dynamics, and continuum mechanics, providing seamless, physics-based prediction of material response across length and time scales. Current efforts also explore machine-learned interatomic potentials and quantum-to-continuum links that connect this work with our Discrete Physical Mathematics activities.

Turbulence and flow physics modelling

From the pioneering work by Prof Osborne Reynolds to the present day, we develop a suite of approaches that span different needs, from low-cost algebraic methods to high-fidelity approaches to direct simulation, and everything in between.

-

Turbulence modelling

We refine and develop Reynolds-averaged Navier–Stokes (RANS) models for steady and unsteady flows, including transitional flows, those with heat transfer and other phenomena such as magnetohydrodynamics.

-

High fidelity simulation

We develop and routinely apply scale resolving methods such as large eddy simulation, direct numerical simulation and hybrid RANS-LES methods. These methods permit higher accuracy and more direct prediction of the unsteady phenomena relevant to thermomechanical fatigue and acoustics.

-

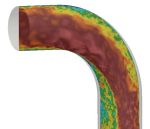

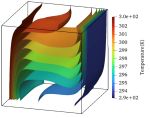

Heat transfer

We develop models and methods for a range of heat transfer problems involving natural/forced convection, conjugate heat transfer and multiscale effects. A particular focus has been advanced wall treatments for turbulent flows.

-

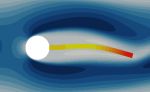

Fluid structure interaction

We have worked on a range of methods to model the coupled response of the surrounding fluid with the immersed structure. This involves both rigid and flexible bodies. Methods include overset grid and the immersed boundary method.

Materials modelling

Our materials modelling capabilities address critical challenges in energy, aerospace, and infrastructure sectors. We employ a range of computational techniques, from atomistic simulations to continuum models, often developing novel hybrid approaches that capture the essential physics while maintaining computational efficiency. Our strong links with experimental facilities enable validation and refinement of our predictive models.

-

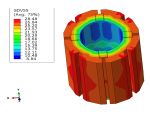

Welding and residual stress

We are world leaders in predicting welding-induced residual stresses and their effects on structural integrity. Our models capture the complex thermo-metallurgical-mechanical interactions during welding, including phase transformations, dilution effects, and post-weld heat treatment. We develop virtual prototyping tools for novel welding processes, including electron beam, laser, and arc-based techniques, supporting nuclear and aerospace manufacturing.

-

Quasi-brittle materials

We specialise in modelling concrete, nuclear graphite, and other quasi-brittle materials using damage mechanics, fracture mechanics, and discrete approaches. Our continuum damage mechanics models predict crack initiation and propagation under complex loading conditions. We develop meso-scale models that explicitly represent material heterogeneity, enabling realistic predictions of localised failure and size effects.

-

Composites

We advance computational methods for polymer composites, from manufacturing process simulation to in-service performance prediction. Our work includes cohesive zone modelling of delamination, multi-scale analysis of fibre-matrix interfaces, and prediction of fatigue damage evolution. We develop models for composite bonded joints and repairs, addressing challenges in aerospace and renewable energy applications.

-

Metallic materials

The state-of-the-art methodologies being developed in our research group enable highly efficient microstructure engineering and modelling by integrating algebraic topology with graph theory and high-performance computing. We are advancing the next generation of tools for multiscale and multidimensional microstructure characterisation and design of complex-structured alloys intended for extreme environments. These approaches facilitate physically realistic simulations of a wide range of mechanical processes—including severe plastic deformation, dynamic impact loading, irradiation, corrosion, and welding—thereby paving the way for innovative data-driven materials engineering.

Future simulation tools

We develop advanced simulation tools that integrate emerging technologies, high-fidelity models, and data-driven approaches to tackle engineering challenges of tomorrow. By combining optimisation algorithms, machine learning, and high-performance computing, we create predictive, scalable solutions that support faster design cycles, real-time analysis, and decision-making across industries.

-

Synthetic environments and digital twins

We work on the development of digital platforms which provide real-time updates, blending traditional engineering simulation with gaming platform physics to facilitate interactive analysis and ‘human in the loop’ interactive design. Live data sources can be incorporated for continuous on-site sensors.

-

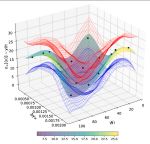

Design optimisation and uncertainty quantification

Our expertise in design optimisation and uncertainty quantification leverages advanced computational techniques to enhance the performance and reliability of engineering systems. By employing sophisticated optimisation algorithms, we can explore high-dimensional parameter space in a far more complete manner than before. Uncertainty quantification then allows engineers to identify and explore key sensitivities and isolate critical aspects of the design space. It also permits a deeper understanding of a complex system compared to single state analysis.

-

Artificial intelligence, machine learning and reduced order modelling

We integrate artificial intelligence (AI) and machine learning (ML) with reduced order modelling (ROM) to create computationally efficient yet accurate simulations for complex systems. By training ML models on high-fidelity simulation data, we can enhance the predictive power of our models, enabling faster analysis and interpretation of results in CFD and solid mechanics applications.

-

Future computing architectures

Our team pioneers the adaptation of computational engineering to next-generation computing architectures, ensuring our methods scale with emerging technologies like exascale systems, GPU-based manycore platforms, and quantum computing. By developing algorithms tailored to these architectures, we address complex challenges in CFD and solid mechanics, preparing for the future of high-performance computing.